Stud welding automation

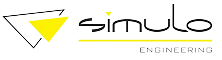

Simulo’s core business is the design and manufacturing of high performance automated systems for stud welding.

Process automation ensures high repeatability and positioning accuracy, significant increase in welding quality and minimization of waste.

Simulo provides installation service, personalized programming, staff training, remote and on-site assistance.

Simulo automated systems integrate high-performance and reliable Soyer® stud welding equipment.

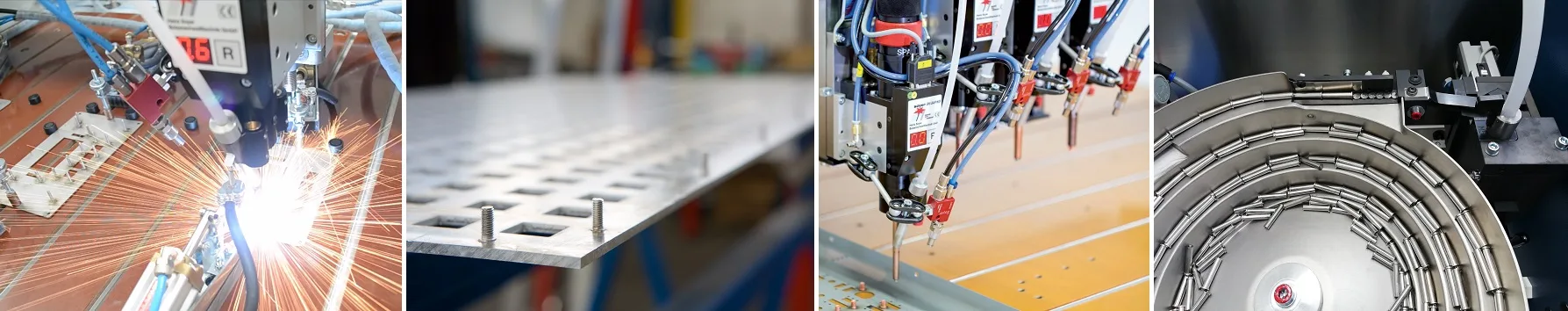

SW800-600 cartesian robot

PLC controlled 3-axis cartesian robot with a working area of 800 x 600mm (X-Y).

Compact machine, designed for those who need to automate stud welding even with low-volume production.

The working table made of thick CNC machined aluminum block and the axes mounted on welded and fully machined steel supports ensure an excellent positioning accuracy of welded studs.

The machine is supplied with welding unit and vibratory bowl stud feeder. It can be equipped with up to two automatic welding heads (for simultaneous welding of different sizes of studs) mounted on pneumatic slide. Various optional equipment is available, including, for example, a protective fluid spraying valve fed by a pressurized tank, as well as special stud feeding devices (e.g. for pick&place).

Workpieces are placed against reference pins on the working table and fixed by pneumatic power clamps.

Further features include fast and easy remote programming, real-time transmission of process parameters via company network and remote assistance service.

Additional customizations according to specific customer needs are possible.

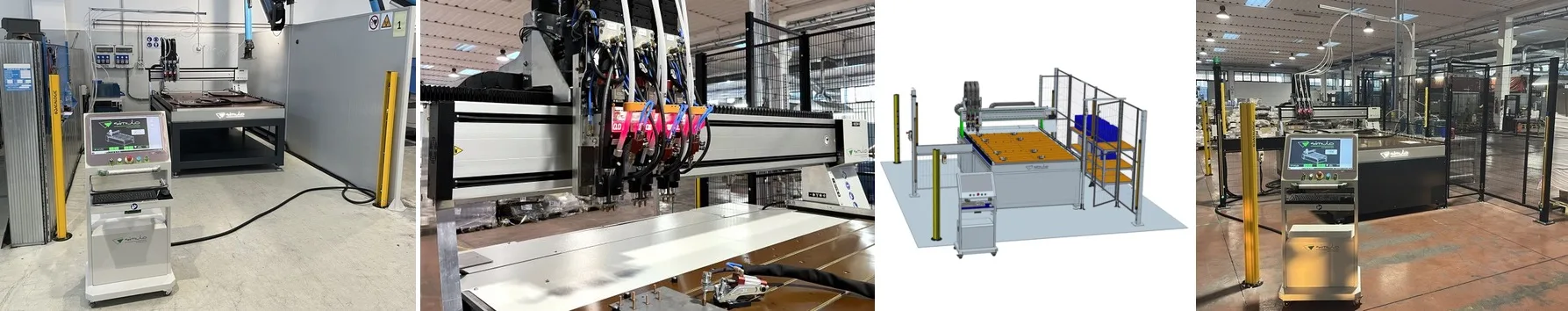

SW1000-1500 and SW1500-2500 cartesian robots

PLC controlled 3-axis cartesian robots with a working area of 1000 x 1500mm and 1500 x 2500mm (X-Y) respectively.

Heavy duty machines for stud welding on large-sized parts, specifically designed and manufactured for intensive operation and simultaneous use of multiple welding heads.

The working table is made of thick CNC machined aluminium block. The axes are mounted on welded and fully machined steel supports. These design measures, together with robust steel machine frame, ensure an excellent positioning accuracy of welded studs.

The machine is supplied with welding unit and vibratory bowl stud feeder. It can be equipped with up to four automatic welding heads (for simultaneous welding of different sizes of studs) mounted on pneumatic slide. Various optional equipment is available, including, for example, a protective fluid spraying valve fed by a pressurized tank, as well as special stud feeding devices (e.g. for pick&place).

Workpieces are placed against reference pins on the working table and fixed by pneumatic power clamps.

Further features include fast and easy remote programming, real-time transmission of process parameters via company network and remote assistance service.

Integrated weld quality monitoring systems, automated components load/unload systems, IPC-based control and several other options are available upon request.

Additional customizations according to specific customer needs are possible.